The most important issues facing EPC contractors and installers are rooftop space utilization efficiency, installation speed, and overall system costs as the world’s installed solar capacity continually increases. Consequently, throughout Europe, Australia, and certain regions of Latin America, the solar mini rail system has quickly emerged as the top option.

Because of its lightweight form, quick installation, low material requirements, and strong adaptability, mini rail is quickly replacing classic long solar profile systems as the current trend.

Technical Specifications

|

Product name

|

Photovoltaic Bracket Mini Rail Solar Mount System

|

Material

|

Aluminum 6005-T5

|

Surface Treatment

|

Anodized silver above 10 micron

|

Length

|

Can be customized

|

Height

|

20mm-100mm

|

Installation

|

Metal roof,flat roof

|

Warranty

|

20 years warranty,25 year service life

|

Packing

|

cardboard or wooden box

|

Less Material = Lower System Cost, Smarter Roof Solutions

Mini rails are shorter than normal rails, which are usually 2 to 4 meters long. Most additional accessories, such as rail transport equipment and rail splices, are reduced. This not only greatly reduce the material need, but it also minimizes the volume and weight of transportation, saving logistics money.

The mini rails are more flexible, is suitable for oddly shaped roofs or limited spaces solar pv flat roof. There is no need for extra cutting, which increases installation efficiency and reduces labor costs.

Also, due to its lightweight design, it is very suitable for lightweight steel roof structures, which further improves the system's safety and applicability.

Speed-Optimized Design = Install More Roofs in the Same Day

ArtSign's Mini rail series is usually pre-cut at the factory, with all other accessories pre-assembled, making installation much simpler.

It doesn't require rail splicing, measuring, or alignment like normal methods do. Just install the mini rail to the roof, assembling the parts, and locking the Photovoltaic Bracket clamps completes the installation.

This effective installation solution reduces projects work time by 30 to 50%, which saving lowers labor costs. Because of its efficiency advantage, which is particularly apparent in multi-roof projects, it is the most cost-effective roof structure for solar panel deployment.

Mini Rail is especially suited for residential and commercial and industrial rooftop due to its high efficiency, lightweight structure, and easy installed. It enables installers finish more work in a day, significantly increasing project delivery speed and enhancing overall cost efficiency.

Modular Structure = Wide Compatibility Across Roof Types

The Mini Rail system will suit different roof types and solar module layouts because of its easy installation and adaptable structural design.

The Mini Rail system is suitable for several flat roof designs as standing seam, corrugated, and trapezoidal metal roofing or some cement roof. By adjusting the rail spacing to suited different solar panels sizes, which ensures better layout adaptability and increased compatibility.

To enhance roof sealing performance, ArtSign also offers custom rubber waterproof pads suitable for different Pv Panels On Flat Roof. These ensure safe, reliable, and long-lasting waterproofing advantages even on complex roof structures.

High-Strength Materials = Reliable Performance in High Wind & Snow Loads

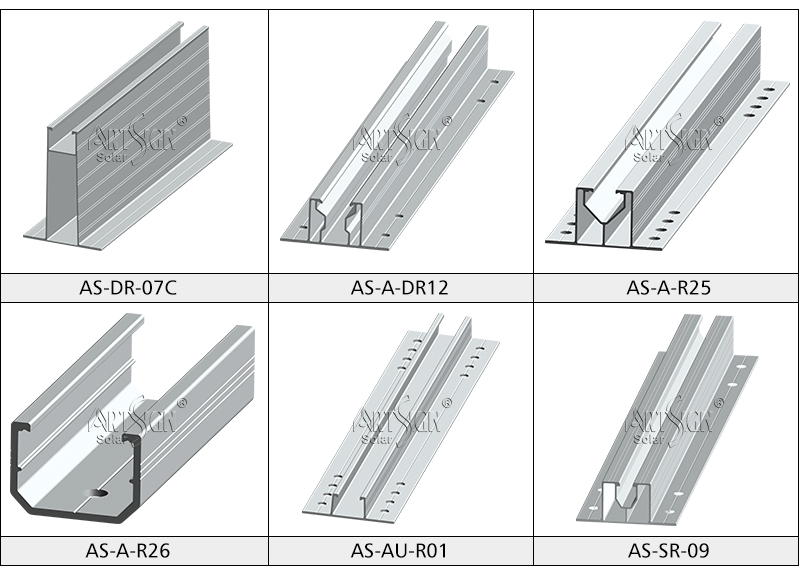

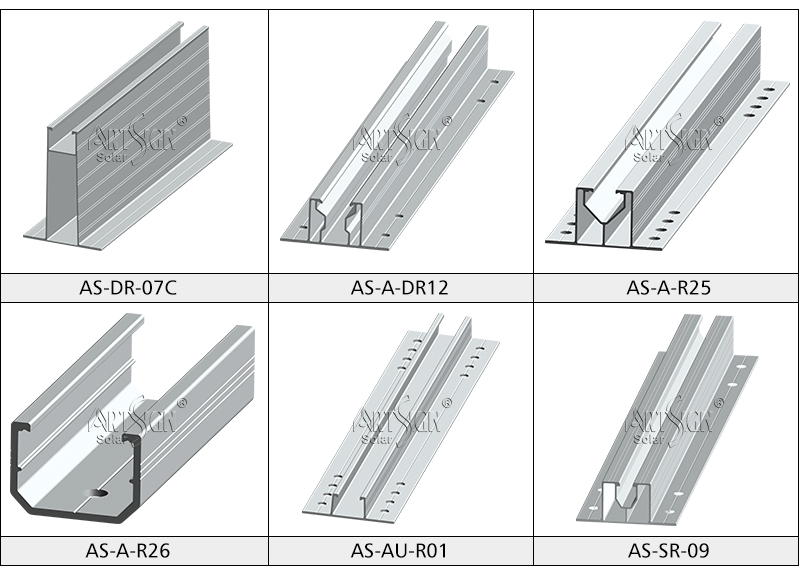

ArtSign's premium mini rail system utilizes 6005-T5 aluminum and 304 stainless steel bolts, ensuring a lightweight structure with exceptional mechanical strength.

Before shipment, products must pass multiple strict tests to ensure compliance with product certification standards such as ISO 9001, CE, and TUV. Even with strong winds or heavy snow areas, it continues to stand stably under pressure.

Mini Rail has been in use for over 20 years in Germany, Poland, the Netherlands, Japan, and other developed countries. Because the mini mount system has earned the trust of numerous EPC contractors and installers due to its stability, durability, and longevity.

Future Trends = Low Cost × High Efficiency × Lightweight Structure

As demand for rooftop solar structures continues to grow, the market is turning toward system solutions that are lighter, require less labor, and offer greater overall cost advantages.

Mini Rail is a perfect fit for this trend because of its special design, lightweight, and quick install speed.

In addition to lowering labor and material costs, it greatly speeds up installation efficiency, making workers to finish more roofing projects in the same time. Because of this, it quickly becoming as the structural option of choice for residential, commercial, and industrial solar installations.

Responding to market trends, ArtSign as a top10 solar mounting system supplier in China, which has designed the Mini Rail system, optimized for global rooftop projects. This system offers huge improvements in structural reliability, installation efficiency, and adaptability to various roof types by utilizing more than 20 years of manufacturing experience and global market knowledge. It enables clients to finish superior projects more quickly and cheaply.

The Mini Rail System from ArtSign is a rooftop solar solution that is ready for the future, not just a mounting system.

Through skilled design, standardized manufacturing, and worldwide experience, we will continue to propel global rooftop solar growth, efficiency, and cost decreases.

For any inquiry of solar panel mounting system, pls contact us, E-mai:sales@artsign.net.cn, Whatsapp / Wechat / Skype:+008618030235875, thanks.