In the solar industry, time is money. As global demand for clean energy continues to grow, solar installation companies are under pressure to deliver efficient, high-quality projects in shorter timeframes. One of the most effective ways to cut down costs and improve productivity is through the use of advanced solar mounting designs. These innovations simplify installation, minimize the need for specialized tools, and reduce labor-intensive tasks on-site.

Traditional solar mounting systems often require multiple steps, precise alignment, and numerous components that must be assembled piece by piece. This can slow down installation crews, increase the risk of errors, and demand more experienced labor. In contrast, modern solar mounting solutions are engineered for simplicity, offering pre-assembled or modular systems that make setup faster and easier.

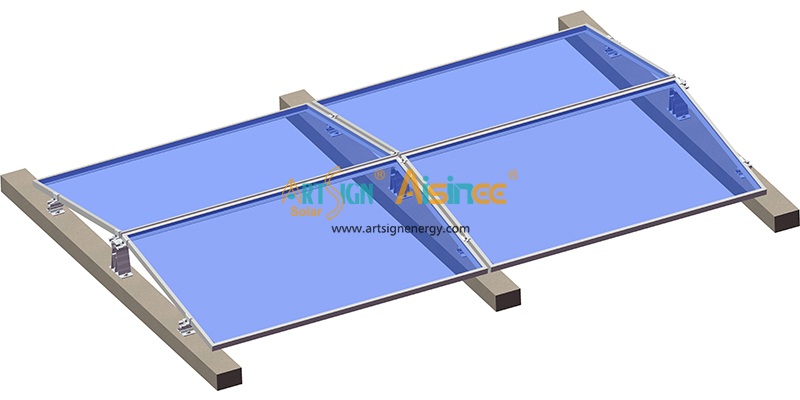

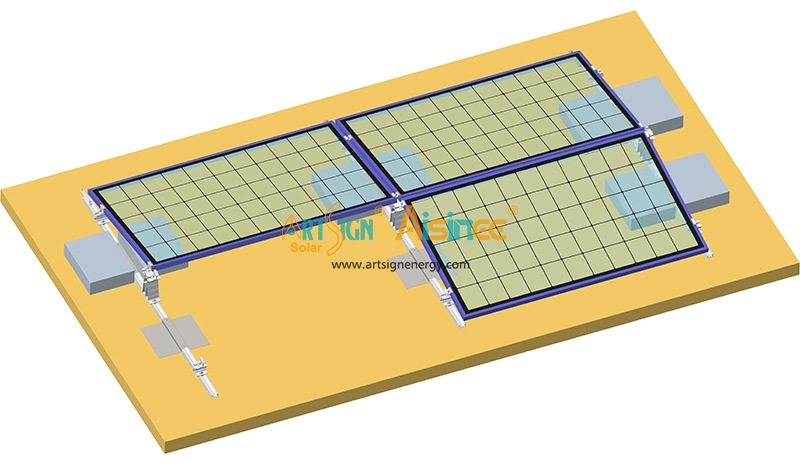

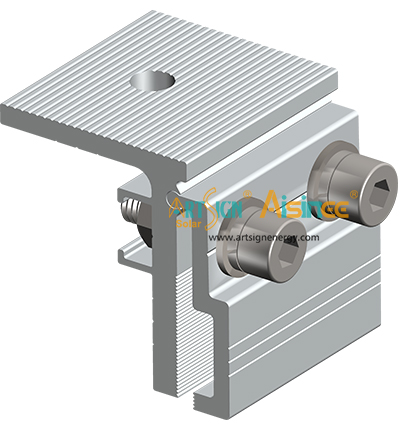

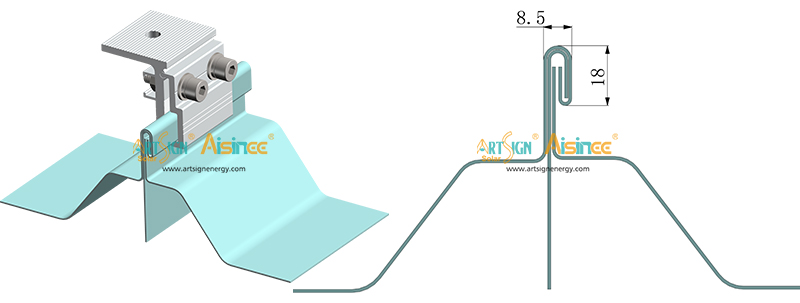

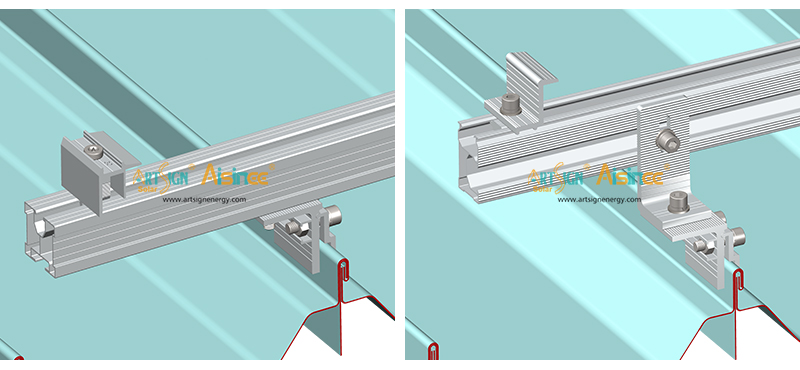

Pre-assembled components are one of the biggest time-savers. Instead of spending hours sorting, aligning, and connecting parts, installers can use mounting brackets, rails, and clamps that arrive ready to install. Many systems now feature “click-in” or “slide-in” mechanisms that eliminate the need for drilling or complex bolting. These user-friendly designs not only reduce installation time but also help maintain consistency and quality across projects.

Another innovation that improves efficiency is the use of lightweight materials such as aluminum alloys. These materials are strong yet easy to handle, cutting down on the physical strain for workers and speeding up transportation and assembly. At the same time, precision manufacturing ensures that components fit perfectly together, reducing the need for on-site adjustments or rework.

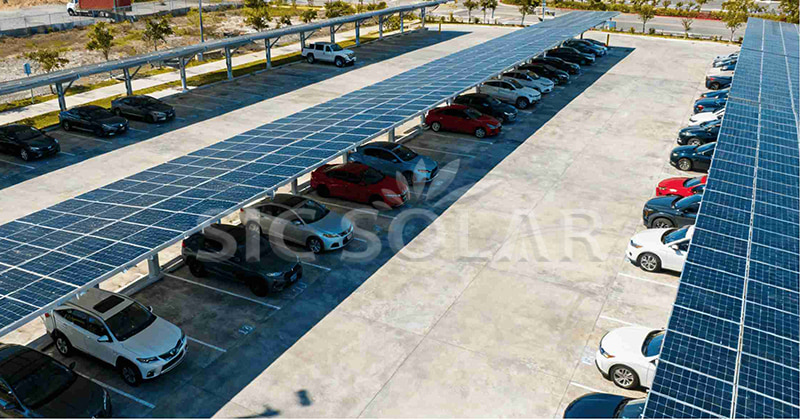

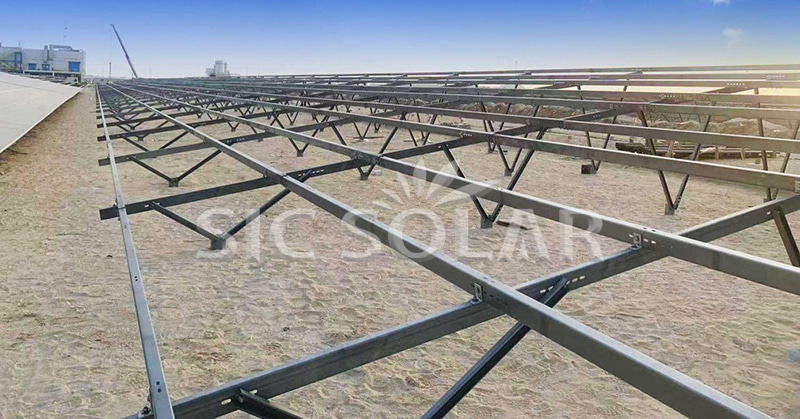

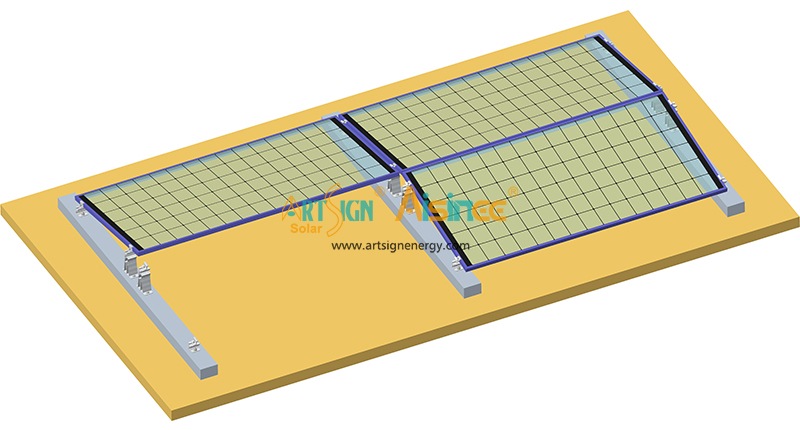

Companies like SIC Solar, a professional manufacturer of photovoltaic mounting systems, are helping lead this transformation. Their product range includes advanced roof and ground mounting solutions designed for quick installation, stability, and adaptability across diverse project environments. By optimizing structure design and minimizing the number of required components, SIC Solar enables installation teams to complete more work with less effort and fewer man-hours.

Additionally, advanced designs now integrate cable management features directly into the mounting systems. This eliminates the need for separate clips and ties, reducing the number of installation steps while maintaining a clean and safe setup. Some systems also include adjustable tilt angles or modular bases, which allow flexibility across uneven terrains and roof types without adding extra parts or labor.

Fewer parts, lighter materials, and faster connections all translate into significant savings. Installers can finish more projects within the same timeframe, lower their labor costs, and reduce overall project expenses—without compromising quality or durability.

By embracing advanced mounting designs from experienced suppliers like SIC Solar, the solar industry is not only improving installation efficiency but also making clean energy deployment more scalable, reliable, and cost-effective worldwide.