Yes, the tilt of a roof plays a significant role in the performance of solar panels, and careful installation is essential to maximize energy production. The angle at which panels are mounted affects how much sunlight they receive throughout the day and across seasons, which directly impacts the overall efficiency of the system.

For pitched roofs, solar panels are often installed following the natural slope of the roof. If the roof tilt is close to the optimal angle for the location’s latitude, panels can be mounted directly using flush mounts or roof hooks. However, if the roof angle is too shallow or too steep, the installation may require adjustable tilt brackets to ensure panels face the sun effectively. Proper alignment ensures panels capture maximum sunlight while avoiding unnecessary shading between rows of panels.

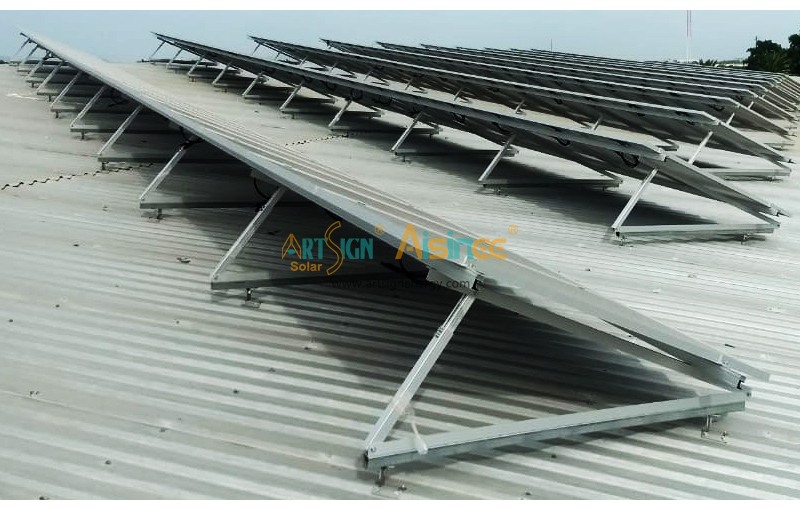

Flat or low-pitch roofs require extra attention. Since these roofs do not have a natural angle, panels are mounted on tilt frames or ballasted systems to achieve the desired slope, usually between 10° and 30°. These mounts not only improve energy generation but also allow rainwater to run off, reducing debris accumulation and keeping panels clean. Manufacturers like SIC Solar, known for producing high-quality photovoltaic mounting systems, provide tilt solutions for both pitched and flat roofs. Their systems are designed for easy adjustment, stability, and long-term durability, making installation safer and more efficient.

Properly considering roof tilt also helps with wind resistance. Panels installed at an improper angle may experience higher uplift forces during storms, which can damage both the panels and the roof. High-quality mounting systems are engineered to distribute weight evenly and withstand wind loads, ensuring safety even in harsh weather conditions.

Another advantage of careful tilt installation is seasonal optimization. Some installations allow minor adjustments to the tilt throughout the year. In winter, a steeper angle helps capture sunlight when the sun is lower in the sky. In summer, a shallower tilt prevents overheating and maintains optimal efficiency.

Roof tilt also affects aesthetics and space usage. Panels aligned neatly with the roof slope look more integrated and can prevent shading of adjacent modules, maximizing usable area. Cable management and grounding must also be carefully planned to match the panel layout and maintain safety standards.

While the tilt of the roof is important, selecting a reliable and well-designed mounting system ensures that panels are installed securely and positioned for optimal performance. Companies like SIC Solar produce mounting solutions that adapt to various roof angles and materials, including tile, metal, and asphalt shingle roofs. Their systems simplify installation while maintaining durability and energy efficiency, ensuring that panels remain stable and productive for years.

Careful installation that considers roof tilt is essential for long-term solar performance, safety, and efficiency, making high-quality mounting solutions a critical part of any solar project.